Pour a Floating Concrete Floor 6 Steps (with Pictures) Instructables

The benefits of floating slab construction for houses are: Don't require a 8'-0" basement wall Don't require a wood flooring system Less concrete and forming is required making for a more economical and ecological construction Cheaper house insurance because there is no basement to flood or chance of Radon gas infiltration.

power floated concrete floor Floors Pinterest Verandas, Modern and Spaces

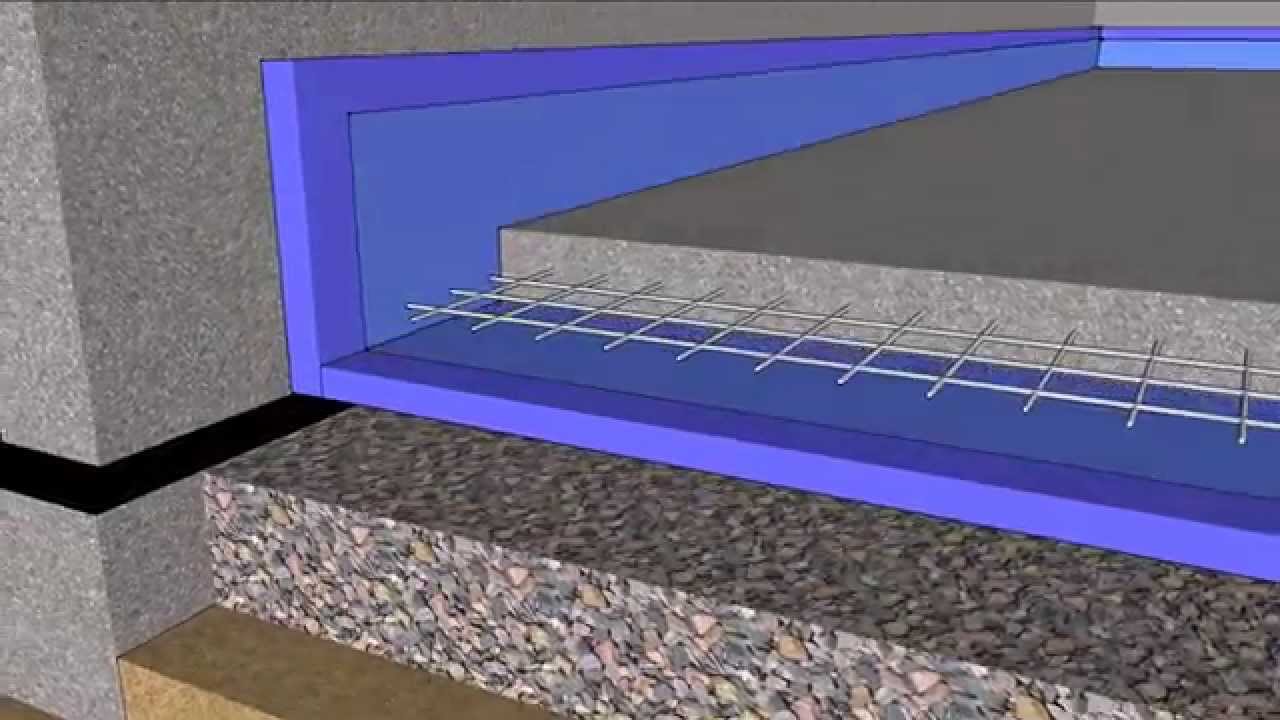

A floating slab, also known as a float slab foundation, is a type of concrete foundation that is constructed by pouring a reinforced concrete slab directly over the soil. Unlike traditional concrete foundations, which are anchored to footings that are dug deep into the ground, floating slabs are designed to "float" on top of the soil. This.

Power Floated Concrete Flooring Nationwide Concreting Ltd

The concrete slab should be level within ⅛" over 8-10 feet, which is standard for hardwood flooring. Then, we recommend covering unsealed concrete with 6-mil polyethylene fabric to block moisture from wicking up the concrete to the hardwood floor. Once your subflooring is level and sealed, you can assemble your Steller Floor right then and.

How to create Floating Concrete Slab Construction & Engineering Arena

A floating floor is a flooring installation that does not require the use of nails. Instead of nailing down wood planks, you attach them by snapping them together like a puzzle. So, the floor is more or less "floating" over the substrate rather than being firmly attached to it.

Concrete Floor Floating Flooring Guide by Cinvex

Floating flooring refers to the method of installation used for a variety of floor types, including laminate, vinyl, and engineered planks. The term is most closely tied to laminate flooring installations, although it's found its way to other areas over the years as well.

Floating Slab Basement Floor Flooring Site

Floating floors need expansion gaps of 1/4-inch to 1/2-inch along each wall to allow slight dimensional changes due to temperature and humidity. A floating hardwood floor in a controlled atmosphere of 70 degrees Fahrenheit and 35% relative humidity will remain basically stable.

Concrete Floor Floating Flooring Tips

How to Install a Floating Floor A step-by-step plan for putting down an engineered wood floor. by Joseph Truini Skill 1 5Easy It's like piecing together a puzzle with basic tools, except there's lots of kneeling and getting up and down. Cost $8 to $18 per square foot Estimated Time 8 to 10 hours

Pour a Floating Concrete Floor 6 Steps (with Pictures)

Costs can range from $2 per square foot for a basic to $30 or more for high-end artistically rendered floors. Basic design: $2 to $6 per square foot. A basic concrete floor design includes pouring the slab or overlay, then a basic polishing and single colorizing treatment (staining or dyeing).

Pour a Floating Concrete Floor 6 Steps (with Pictures)

Step 1: Patch the Existing Concrete Slab. We used Quikcrete's Vinyl Concrete Patcher to fill the cracks and to smooth the floor as much as possible. Step 2: Creating the "Floating" Layer We covered the floor with Home Depot's HDX 6 mil Black plastic sheet and then laid wire re-mesh sheet (also from Home Depot) over top of the plastic.

Power Floated Concrete Flooring Nationwide Concreting Ltd

The steps below cover how to install a floating floor. Full details of the procedure are available in our product literature and this should be consulted prior to starting any work. Concrete slabs should be allowed to dry out fully prior to the installation of Thermafloor TF70 (average 1 day per mm of slab thickness)

Power floated concrete floors installed,Devon,Dorset,Somerset,Cornwall,Southwest

Detail of floating floor over concrete. Detail of floating floor over joists. A floating floor is a floor that does not need to be nailed or glued to the subfloor. The term floating floor refers to the installation method, but is often used synonymously with laminate flooring. It is applied now to other coverings such as floating tile systems.

Floating Concrete Floor Construction Flooring Tips

Install a floating subfloor over concrete slab Because they interlock and sit directly on the slab, floating subfloor panels are ideal for concrete surfaces that are level and clear of obstructions. Available in many models, materials and prices, they provide an effective moisture barrier and create a solid base for a finished floor.

Pour a Floating Concrete Floor 6 Steps (with Pictures)

Floating floors have become increasingly popular for many types of floor coverings. The term "floating floor" does not refer to a type of flooring material, but rather to a method of installation that can be used with a variety of materials, including laminates, engineered hardwood, and luxury vinyl flooring. In this method, individual planks (or in some cases tiles) interlock edge-to-edge to.

Floating Concrete Floor Construction Clsa Flooring Guide

A floating slab is the basic foundation structure used for buildings that don't have basements (garages, sheds, barns, and even some homes in the high water table or coastal areas). Concrete floating slabs may and, in areas that experience freezing temperatures, must be insulated.

floating basement floor slab Camila Travis

A concrete finish is accomplished through a power float to smooth and level a hardened concrete floor once water has evaporated from the ground. A power float machine utilises its rotating circular pans to achieve a smooth and polished finish. Concrete finishes are typically found across all sectors, but are ideal for areas with high traffic.

Floating Floor On Concrete / It can easily be installed on top of an existing concrete slab

$51-100 Introduction In this article, we'll show you the tools and techniques you need to get a smooth, durable finish on concrete. We'll also tell you how to know when the concrete is ready for each phase of the finishing process.